Hardware designer for the cheese factory

since 1956

CHEESEMAKING MATERIAL

Sustainable investment

Roussel Inox materials are designed and manufactured in our factory floors in France, a country with a rich cheesemaking tradition, and they cater for processing all types of milk. They are both robust and easy to use.

Our machines and accessories, resulting from our extensive knowledge of the cheesemaking industry, are lasting investments, tailor-made for our clients. For us, this sustainable property, the antithesis of planned obsolescence, contributes greatly to protecting our environment.

Our realisations are evidence of not only know-how in excellence, but also of an ongoing quest for technological innovation, in tune with the increasing demands and changes in our clients’ trade.

All the components of our materials are subject to a certificate of conformity.

MILK AND WHEY PROCESSING

Our machines (whey separation units, pasteurisation platforms, etc.) are delivered by skid once all the modules have been manufactured and tested in our workshops. The only phase to be carried out at your production site is the connection phase, thereby reducing disruption to a minimum.

BLUE-VEINED CHEESES

We at Roussel Inox, here in the heart of the Roquefort cheese production area, have been supplying the manufacturers of the king of cheeses with production material for over sixty years. Which goes to show that we know just about everything there is to know about blue-veined cheese! We adapt the slow-stirring technique to the type of product required, so as to optimise the quality of the curd.

PRESSED CHEESES

The average capacity of our vats ranges from 3,000 to 12,000 litres and can be increased when required. We have developed an automatic pre-pressing device with a clean-in-place system. We produce cheese moulding machines adapted to our customers’ capacities, be they farmhouse cheesemakers or major industrial producers.

SOFT CHEESES

Small-volume production vats, tubular moulding machines, moulding conveyors or draining belts: our products are adapted to soft-cheese technology. Their format is defined precisely according to our clients’ projects and production capacities.

LACTIC CHEESES

We are one of the few manufacturers who design material for lactic cheeses. Filter presses, mechanised draining, flipping, top-stacking, bottom-stacking, – a wide range of material, that can be adjusted and adapted. We also manufacture specific curdling vats.

FRESH CHEESES

We create and design vats for producing yoghurt, more specifically aimed at farmhouse production (small volumes), so as to help and guide producers with diversification.

SPECIAL MACHINES

Both because of tradition and because we enjoy a challenge, we also design, upon request, special machines that meet your specific farmhouse or industrial requirements, even unrelated to cheesemaking. Our washing solutions can also be applied to these machines.

WASHING

TACTfulness !

Roussel Inox pays particularly close attention to food security. With our high-performance, easy-to-handle machines, we aim to help our customers to obtain thorough cleaning and meticulous disinfection of their equipment, in optimal working conditions. The main features of our solutions are the flexibility of their utilisation, their adaptability and their efficiency. They enable you to clean with TACT (temperature, mechanical action, concentration, time) and… with tact, with finesse.

Roussel Inox is increasingly steering its technical prowess towards saving water. We ensure that our machines consume water moderately and reasonably.

WASHING TUNNELS

Our washing tunnels, for cleaning and then drying boxes, blocks, moulds and grids, allow the items to be moved along a covered conveyor belt. The full cycle includes prewashing, washing and rinsing. To reduce water consumption, the rinsing water is recycled in the prewash.

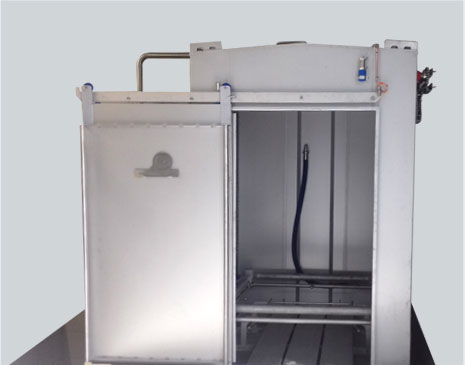

CABINETS AND TANKS

Our wash cabinets and turbo-wash tanks are much more than a mere kit with stainless steel walls! In both our design department and our production floor, they are designed in accordance with the requirements that come first and foremost for all of our machines: reliability and user-friendliness.

The cabinet works completely independently, on a prewash-wash-rinse cylce.

The tank allows materials to be steeped and provides optimal cleaning of impact zones or mechanical action areas that are hardest to reach.

CIP

Our Clean-in-place (CIP) skids enable you to meet maximal hygiene standards without the slightest need for dismantling material (machines, pipework). They are extremely flexible and easy to use. The duration of the wash-cycle and the amount of detergent to be used can be defined by you.

AFTER-SALES SERVICE

Our added value

Here at Roussel Inox, we make sure that you avail of high-speed maintenance and troubleshooting.

We monitor the machines periodically. In the event of a malfunction, our staff do their utmost to ensure immediate service.

We pay close attention to the scalability of the machines: when they near their end of life, we can work on them again and proceed with migration towards new-generation technologies.

Finally, when we service our machines, we fit them with a remote maintenance system which allows problems to be diagnosed and solved from a distance – and provides you with even more efficient after-sales service!

SOLUTIONS RI

OPTIMIZE YOUR PRODUCTIVITY

YOUR TAILOR-MADE PROJECT

EXPERT DESIGNER

CHEESEMAKING

MATERIAL

CUSTOM

DESIGNED

PRODUCTS

FRENCH

MANUFACTURING

QUALITY

GUARANTEE

EXPERT

TECHNICIANS